Life-saving lab on a chip for just 1 cent

Carrying out professional research in order to produce or manufacture anything these days is quite expensive. While developed nations do not face just as much trouble, under-developed countries have a tough time surviving a battle against lethal diseases such as malaria, tuberculosis and HIV. To solve this issue, researchers at the Stanford University School of Medicine have developed a way to produce a cheap and re-usable diagnostic “lab on a chip” with the help of an ordinary inkjet printer.

At the production cost of as little as 1 cent per chip, the new technology has the potential of ushering in a medical diagnostics revolution like the kind brought on by low-cost genome sequencing, said Ron Davis, PhD, professor of biochemistry and of genetics and director of the Stanford Genome Technology Center.

A study describing the technology was published online on February 6 in the Proceedings of the National Academy of Sciences.

“Enabling early detection of diseases is one of the greatest opportunities we have for developing effective treatments,” Esfandyarpour said. “Maybe $1 in the

A two-part system

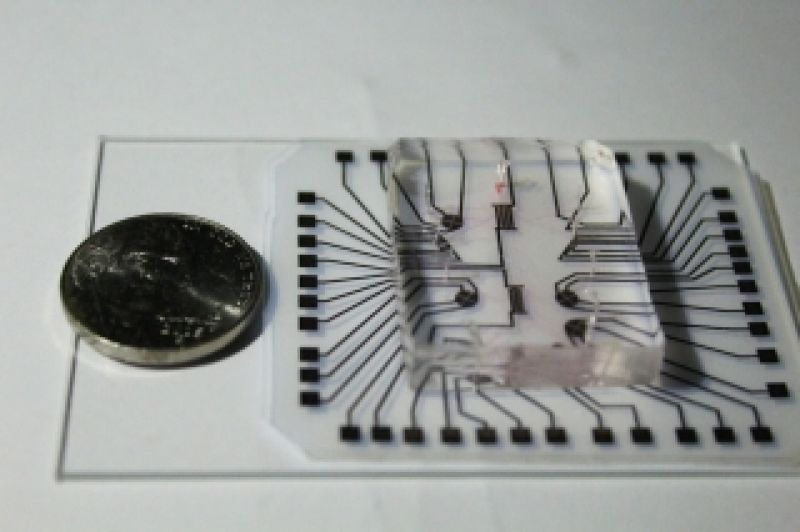

A combination of microfluidics, electronics and inkjet printing technology, the lab on a chip is a two-part system. The first is a clear silicone microfluidic chamber for housing cells and a reusable electronic strip. The second part is a regular inkjet printer that can be used to print the electronic strip onto a flexible sheet of polyester using commercially available conductive nanoparticle ink.

The lab on a chip comprises a clear silicone microfluidic chamber for housing cells and a reusable electronic strip — a flexible sheet of polyester with commercially available conductive nanoparticle ink.

The lab on a chip comprises a clear silicone microfluidic chamber for housing cells and a reusable electronic strip — a flexible sheet of polyester with commercially available conductive nanoparticle ink.

The lab on a chip comprises a clear silicone microfluidic chamber for housing cells and a reusable electronic strip — a flexible sheet of polyester with commercially available conductive nano particle ink.

“We designed it to eliminate the need for clean-room facilities and trained personnel to fabricate such a device,” said Esfandyarpour, an electrical engineer by training. One chip can be produced in about 20 minutes, he said.

Designed as a multifunctional platform, one of its applications is that it allows users to analyze different cell types without using fluorescent or magnetic labels that are typically required to track cells. Instead, the chip separates cells based on their intrinsic electrical properties: When an electric potential is applied across the inkjet-printed strip, cells loaded into the microfluidic chamber get pulled in different directions depending on their “polarizability” in a process called dielectrophoresis. This label-free method to analyze cells greatly improves precision and cuts lengthy labeling processes.

The tool is designed to handle small-volume samples for a variety of assays. The researchers showed the device can help capture single cells from a mix, isolate rare cells and count cells based on cell types. The cost of these multifunctional biochips is orders of magnitude lower than that of the individual technologies that perform each of those functions. A standalone flow cytometer machine, for example, which is used to sort and count cells, costs $100,000, without taking any operational costs into account.

Potential to democratize diagnostics

“The motivation was really how to export technology and how to decrease the cost of things,”

The low cost of the chips could democratize diagnostics similar to how low-cost sequencing created a revolution in health care and personalized medicine,

The technology has the potential to not only advance health care, but also to accelerate basic and applied research. It would allow scientists and clinicians to potentially analyze more cells in shorter time periods, manipulate stem cells to achieve efficient gene transfer and develop cost-effective ways to diagnose diseases, Esfandyarpour said. The team hopes the chip will create a transformation in how people use instruments in the lab. “I’m pretty sure it will open a window for researchers because it makes life much easier for them — just print it and use it,” he said.